FAQ

Frequently Asked Questions

General Questions

WHAT IS SYNTHETIC TURF?

HOW IS SYNTHETIC TURF MADE?

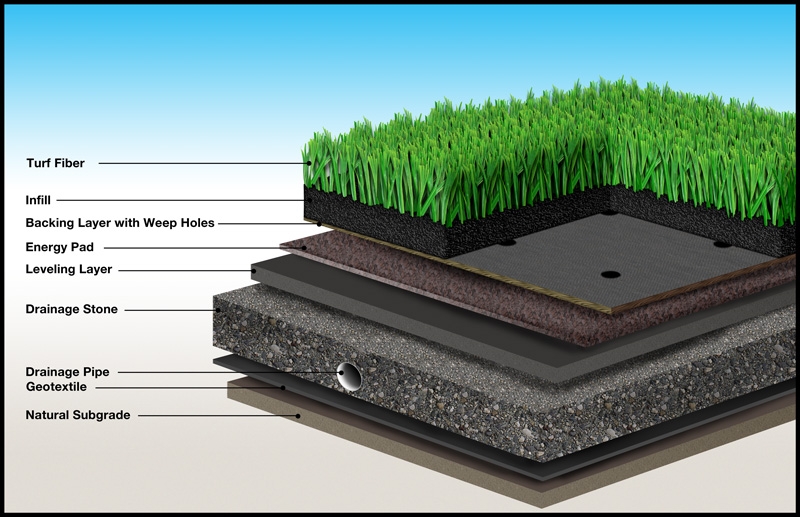

Most synthetic turf systems installed today include a drainage layer, a multi-layered backing system, and resilient “grass” blades that are infilled with a granular filler to resemble natural turf. “Infilled” means that the man-made grass blades are interspersed with a top soil created with sand and/or granulated recycled tire rubber or other infill materials that provide the necessary stability, uniformity, and resiliency. Each blade customarily stands above the infill material. The typical blade length and system characteristics are determined by the specific activity requirements. In some applications, the synthetic turf system includes a pad or elastic layer underneath the turf, often in combination with lower pile height and less infill.

HOW IS THE NEW GENERATION OF SYNTHETIC TURF DIFFERENT FROM THAT OF THE PAST?

WHY HAS SYNTHETIC TURF BECOME SO POPULAR OVER THE PAST FEW YEARS?

Synthetic turf is a smart solution for playing fields and landscape that have become unsafe and unsightly from overuse or severe climatic conditions. A grass field simply cannot remain lush and resilient if it is used more than three to four days a week, or in the rain, or during the months when grass doesn’t grow. This fact, coupled with an escalating need for durable fields that accommodate multiple sports teams and activities, the high cost of maintaining a grass sports field, and the need to conserve water, have prompted a rising number of schools and parks to turn to synthetic turf to meet their program needs. Today’s synthetic turf is designed to simulate the experience of practicing and playing on the best grass fields.

Demand has grown to the point where more than 8,000 multi-use synthetic turf sports fields are now enjoyed in North American schools, colleges, parks and professional sports stadiums. About half of all NFL teams currently play their games on synthetic turf and, since 2003, over 70 FIFA U-17 and U-20 World Cup matches have been played on synthetic turf soccer fields.

WHAT ARE THE MOST POPULAR SYNTHETIC TURF INFILLS AND THEIR SPECIFIC USES?

ENVIROFILL

We use Envirofill that has anti-microbial properties which help prevent bacteria, mold, and mildew growth. This makes it a more hygienic option for sports fields, playgrounds, and any synthetic turf that man and pets play on.

HYDROCHILL

Evaporating moisture removing heat, leaving a cooler, more comfortable surface for families and pets. The ambient temperature does not necessarily dictate surface temperature . The solar radiation time period, sun’s angle, cloud cover, wind, and other elements all contribute to the temperature of the surface.

T- COOL

Cool® Infill

T°Cool® is an eco-friendly solution that cools synthetic turf by coating the infill to combat the heat and make the fields cooler, safer, and more playable.

HOW POPULAR IS SYNTHETIC GRASS FOR LANDSCAPE AND RECREATION USE?

HOW IS SYNTHETIC TURF BEING USED IN THE LANDSCAPE AND RECREATION MARKET?

Thousands of homes, businesses, golf courses, municipalities, parks and tourist attractions like Disneyland and Steve Wynn’s Las Vegas resorts have turned to synthetic grass to provide a lush, attractive landscape solution that requires minimal resources and maintenance while saving millions of gallons of water each year. It is also a smart way to beautify public spaces such as highway medians and airport landing strips that would otherwise be difficult and expensive to maintain. Synthetic grass reduces city maintenance costs, freeing tax dollars for other purposes.

Synthetic turf also promotes greater utilization of land, as you can do more with the same space surface than with natural grass. Rooftops once deemed unusable for high rises and residential buildings can now feature inviting green area. Hotels that had to restrict the use of lawns for parties and events can now schedule as many functions as they can book.

Health & Enviromental Imact

HOW DOES SYNTHETIC TURF IMPACT THE ENVIRONM

Synthetic turf has a measurable, positive impact on the environment. Depending on the region of the country, a typical grass sports field requires between 500,000 to a million gallons of water or more each year. During 2010, between four to eight billion gallons of water were conserved through its use. According to the U.S. Environmental Protection Agency (EPA), the average American family of four uses 400 gallons of water a day. Therefore, a savings of four to eight billion gallons of water equates to the annual water usage of over 27,000 to 55,000 average American families of four.

Tax credits and rebates are being offered to residential and corporate users by an increasing number of local governments in light of the tremendous impact on water conservation. The Southern Nevada Water Authority estimates that every square foot of natural grass replaced saves 55 gallons of water per year. If an average lawn is 1,800 square feet, then Las Vegas homeowners with synthetic turf could save 99,000 gallons of water each year or about $400 annually. In Atlanta, homeowners could save $715 a year, not including much higher sewer charges.

The estimated amount of synthetic turf currently installed has eliminated the need for millions of pounds of harmful pesticides and fertilizers, which has significant health and environmental implications. For example, according to the North Carolina Department of Environment and Natural Resources, polluted storm water runoff is the number one cause of water pollution in their state, with common examples including over fertilizing lawns and excessive pesticide use.

In addition, synthetic turf helps reduce noxious emissions (the EPA reports that a push mower emits as much pollution in one hour as 11 cars and a riding mower emits as much as 34 cars) and reduces grass clippings, which the EPA states are the third largest component of municipal solid waste in landfills.

IS SYNTHETIC TURF SAFE?

More than 50 independent and credible studies from groups such as the U.S. Consumer Product Safety Commission, and statewide governmental agencies such as the New York State Department of Environmental Conservation, New York State Department of Health and the California Environmental Protection Agency, have validated the safety of synthetic turf (see Position Statements to learn more).

Recent highlights include:

- In October 2010, the California Office of Environmental Assessment completed its multi-year study of air quality above crumb rubber infilled synthetic turf, and bacteria in the turf, and reported that there were no public health concerns.

- In July 2010, the Connecticut Department of Public Health announced that a new study of the risks to children and adults playing on synthetic turf fields containing crumb rubber infill shows “no elevated health risks.”

- The California EPA released a report dated July 2009 which indicated there is a negligible human health risk from inhaling the air above synthetic turf.

- Independent tests conducted by the New York State Department of Environmental Conservation and New York State Department of Health, released in May 2009, proved there were no significant health concerns at synthetic turf fields.

- In July 2008, a U.S. Consumer Product Safety Commission staff report approved the use of synthetic turf by children and people of all ages.

SHOULD I BE CONCERNED ABOUT LEAD IN MY FIELD?

More than 50 independent and credible studies from groups such as the U.S. Consumer Product Safety Commission, and statewide governmental agencies such as the New York State Department of Environmental Conservation, New York State Department of Health and the California Environmental Protection Agency, have validated the safety of synthetic turf (see Position Statements to learn more).

Recent highlights include:

- In October 2010, the California Office of Environmental Assessment completed its multi-year study of air quality above crumb rubber infilled synthetic turf, and bacteria in the turf, and reported that there were no public health concerns.

- In July 2010, the Connecticut Department of Public Health announced that a new study of the risks to children and adults playing on synthetic turf fields containing crumb rubber infill shows “no elevated health risks.”

- The California EPA released a report dated July 2009 which indicated there is a negligible human health risk from inhaling the air above synthetic turf.

- Independent tests conducted by the New York State Department of Environmental Conservation and New York State Department of Health, released in May 2009, proved there were no significant health concerns at synthetic turf fields.

- In July 2008, a U.S. Consumer Product Safety Commission staff report approved the use of synthetic turf by children and people of all ages.

IS CRUMB RUBBER SAFE?

Yes. Crumb rubber infill, made from reclaimed tires, is a popular infill option for many synthetic turf fields. It has been safely utilized since being introduced in 1997, and in playgrounds and tracks for much longer. This resilient material provides enhanced durability and safety. Its use in synthetic turf sports fields and landscape has also kept more than 105 million used tires out of landfills. Crumb rubber has been critically examined and studied since the late 1980’s. Science has proven it to be safe for children and people of all ages (see Research and Latest Thinking and Crumb Rubber FAQs to learn more).

WHAT IMPACT DOES HEAT HAVE ON MY SYNTHETIC TURF FIELD?

During the summer months on hot sunny days, when synthetic turf is exposed to direct sunlight, some synthetic turf fields have reported surface temperatures significantly hotter than the surface temperature of a natural turf field. In such conditions, many coaches will schedule practices and games for the cooler times of day, and limit the number and duration of practices. They will also follow, as STC advocates, the heat-acclimation guidelines published by the National Athletic Trainers’ Association.

Some field managers might opt to water their fields, while others advocate misting the athletes and keeping them properly hydrated. A misting station normally needs only five gallons of water per hour based on full use. On a typical day, when the heat is at its peak for four to six hours, that equals 20 to 30 gallons of water.

ARE ATHLETES PLAYING ON A SYNTHETIC TURF MORE SUSCEPTIBLE TO MRSA/STAPH INFECTIONS?

MRSA and other staph infections strike due to poor hygiene, regardless of type of playing surface. That’s because it is spread by people in close contact with each other, like athletic team members, healthcare providers and patients, children in day care centers, military recruits, firefighters, and many other groups. Recent studies are in agreement. A California EPA report dated July 2009 stated “it is unlikely that the new generation of artificial turf is itself a source of MRSA.”

A Penn State University study released in January 2009 found there was no difference in survival rates of staph on natural grass and synthetic turf surfaces. In addition, it stated that synthetic turf is not a hospitable environment for microbial activity such as staph. The issue goes beyond abrasions, since athletes can get cuts on any playing field – from the most well-manicured or dirt-compacted natural grass to state-of-the-art synthetic turf fields that are regularly irrigated and cleaned.

HOW CAN I LEARN MORE ABOUT SCIENTIFIC STUDIES ON THE HEALTH AND ENVIRONMENTAL SAFETY OF SYNTHETIC TURF?

See Research and Latest Thinking to view unfiltered U.S. and international studies, links to industry resources and new position statements as materials are developed.

Player Usage & Injuries

WHAT IMPACT DOES SYNTHETIC TURF HAVE ON PLAYING TIME?

Made with resilient materials for safety, synthetic turf sports fields are always ready to play on. Traction, rotation and slip resistance, surface abrasion and stability meet the rigorous requirements of the most respected sports leagues and federations.

Made with resilient materials for safety, synthetic turf sports fields are always ready to play on. Traction, rotation and slip resistance, surface abrasion and stability meet the rigorous requirements of the most respected sports leagues and federations.

HOW DOES SYNTHETIC TURF COMPARE TO NATURAL GRASS ON PLAYER INJURY RATES?

Made with resilient materials for safety, synthetic turf sports fields are always ready to play on. Traction, rotation and slip resistance, surface abrasion and stability meet the rigorous requirements of the most respected sports leagues and federations.

So it’s no surprise that recent studies indicate that the injury risk of playing on synthetic turf is no greater than natural grass:

Three 2010 long-term studies published by researchers from Norway and Sweden compared acute injuries on synthetic turf and natural grass. The studies examined the type, location and severity of injuries sustained by hundreds of players during thousands of hours of matches and training over a four to five year period. Many types of acute injuries to men and women soccer players, particularly knee injury, ankle sprain, muscle strains, concussions, MCL tears, and fractures were evaluated. The researchers concluded that the injury risk of playing on artificial turf is no greater than playing on natural grass;

An analysis by FIFA’s Medical Assessment and Research Centre of the incidence and severity of injuries sustained on grass and synthetic turf during two FIFA U-17 World Championships. According to FIFA, “The research showed that there was very little difference in the incidence, nature and causes of injuries observed during games played on artificial turf compared with those played on grass.”

A 2004 NCAA study among schools nationwide comparing injury rates between natural and synthetic turf found that the injury rate during practice was 4.4% on natural turf, and 3.5% on synthetic turf.

Cost, Installation, Maintenance, & Disposal

WHAT ARE THE ADVANTAGES OF CONTRACTING WITH AN STC MEMBER COMPANY?

The STC recommends that you hire a team of professional contractors who are STC members and, if possible, STC Certified members, that you select with the help of a landscape architect and engineer or independent consultant. Visit the Buyers’ Guide and Member Directory to help with your search.

HOW LONG CAN A SYNTHETIC TURF FIELD BE USED?

Synthetic turf sports fields are typically warranted for eight years, but their life expectancy will depend to a great extent on the amount and type of usage and the maintenance it receives. When it comes to landscape applications, synthetic turf can last much longer than fields.

HOW DOES THE COST OF A SYNTHETIC TURF FIELD COMPARE TO A NATURAL TURF FIELD?

A synthetic turf field usually has a higher upfront cost, but the field often pays for itself over 3-4 years, proving to be a highly cost-effective investment. Synthetic turf fields are typically utilized for about 3,000 hours of play per year, with no “rest” required, the equivalent of three to four well-maintained natural turf fields. In addition, synthetic turf maintenance costs are two to three times less than natural turf, since no mowing, irrigation or chemicals are needed. Because of its consistent availability, a synthetic turf field is also a reliable source of rental revenue for schools and communities.

According to Cory Jenner, a landscape architecture professional in Syracuse, N.Y., the cost of installing and maintaining a synthetic turf sports field over a 20-year period (including one replacement field) is over three times less expensive per event than the cost of a grass field over the same period of time. This is because many more events can be held on a synthetic turf sports field. “Financially speaking, artificial turf is more cost-effective over time,” Jenner said. This cost per event advantage is validated by other authorities and field owners.

ARE ALL SYNTHETIC TURF PRODUCTS THE SAME?

No, there are a variety of different types of synthetic turf products and systems. Visit the Buyers’ Guide & Member Directory to browse synthetic turf manufacturers and system builders.

CAN SYNTHETIC TURF HOLD UP UNDER HEAVY USE?

Yes, one of the important advantages of synthetic turf is its ability to hold up under very heavy use. While natural turf shouldn’t be played on during or immediately after a rain storm, after the application of pesticides and fertilizers, or during the months when grass doesn’t grow, synthetic turf is always ready for play. Regular maintenance is important to enable synthetic turf to withstand the heavy use that it is often subjected to.

DOES SYNTHETIC TURF FADE?

Synthetic turf is U.V. stabilized to provide colorfastness, and the warranty typically includes a guarantee against fading for a certain number of years. Be aware of the relative impact that ultra violet rays can have on the life of your field – the greater the intensity of the sunlight, the shorter the lifespan of the fiber. Ask the turf vendor for this information. A field in Texas will not last as long as the same field in Maine.

WHO SHOULD I CONSULT FOR THE INSTALLATION OF A SYNTHETIC TURF SPORTS FIELD?

The STC recommends that you hire a team of professional contractors that you select with the help of a landscape architect and engineer or independent consultant. Visit the Buyers’ Guide and Member Directory to help with your search.

IS MAINTENANCE OF SYNTHETIC TURF REQUIRED?

While much less time and money is required to maintain a synthetic turf sports field than a natural grass field, synthetic turf needs to be maintained to maximize playability and the life of the product. The STC’s Guidelines for Maintenance of Infilled Synthetic Turf Sports Fields (available in English and Spanish) provides essential guidance on proper maintenance techniques and frequency. The Buyers’ Guide and Member Directory will also guide you to specific service providers.

WHERE DO I TURN FOR TECHNICAL GUIDANCE?

The STC’s member companies are the best source of technical guidance. Organizations are listed according to the product or service they provide in the Buyers’ Guide and Member Directory. The STC Resource Center provides technical guidelines, suggestions for funding a field, marketing brochures and lots more information – all available for download without charge. Our website also offers latest research, position statements and white papers.

If you still have questions or require additional information, please contact us at (443) 640-1067 or office@syntheticturfcouncil.org or use our online submission form and we will respond to your inquiry within 24 hours.